Are you aspiring to become a napkin manufacturer and launch your very own napkin company? Producing high-quality napkins requires careful planning, selection of materials, and efficient processes. In this guide, we will walk you through the essential steps to become a successful napkin maker, catering to napkin suppliers and end customers alike.

Step 1: Design and Planning As a napkin manufacturer, your journey starts with determining the type of napkins you wish to produce. Consider factors such as size, color, pattern, and materials in your designs. A well-crafted blueprint will guide your manufacturing process and set the foundation for a successful venture.

Step 2: Materials Selection Choosing the right materials is crucial to ensure the quality and appeal of your napkins. Whether you opt for paper, cloth, or a blend of both, select materials that meet stringent standards and safety requirements. Quality materials will attract napkin suppliers and loyal customers to your brand.

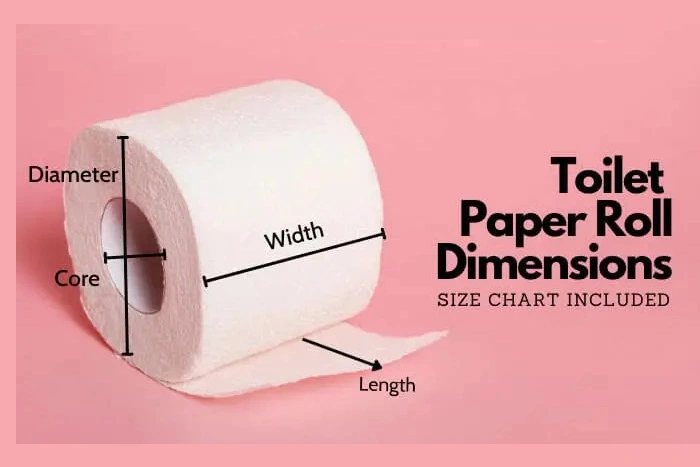

Step 3: Cutting the Material Efficiently cutting the chosen fabric or paper rolls into individual napkin sizes is the next vital step. Precision is key here, and you can either opt for manual cutting or invest in automated cutting machines to increase productivity and accuracy.

Step 4: Printing (if applicable) For napkin manufacturers looking to offer unique designs and patterns, printing is a valuable addition to the production process. Techniques like offset printing or digital printing can transform your napkins and captivate your target market.

Step 5: Embossing or Embroidery (if applicable) If your focus is on cloth napkins, adding special touches like embossing or embroidery can elevate the appeal of your products. These decorative techniques appeal to napkin suppliers and end customers seeking sophisticated options.

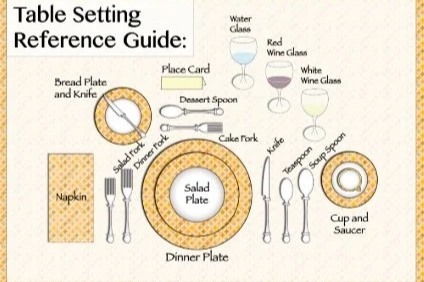

Step 6: Folding Before packaging, expertly folding the napkins enhances their presentation. Different folding styles can cater to varying packaging preferences, making your products stand out in the market.

Step 7: Packaging Careful and attractive packaging ensures your napkins are well-protected during transportation and retail display. Consider stacking individual napkins or assembling them in sets to cater to different customer needs.

Step 8: Quality Control Maintaining a stringent quality control process is vital for any napkin manufacturer. Regular checks for defects, consistency, and adherence to specifications will help establish your reputation as a reliable napkin maker.

Step 9: Distribution Once your napkins are ready for the market, establishing distribution channels to reach napkin suppliers, retail stores, and wholesalers is essential for expanding your brand’s reach.

Step 10: Machine Maintenance and Cleaning To ensure smooth and efficient production, regular maintenance and cleaning of your manufacturing machinery are crucial. This practice minimizes downtime and maximizes productivity.

Becoming a successful napkin manufacturer and establishing your own napkin company requires dedication, attention to detail, and a commitment to quality. By following these steps and focusing on meeting the demands of napkin suppliers and end customers, you can forge a path to success in this industry. Remember to stay abreast of industry regulations and safety standards to ensure your napkin manufacturing business thrives in the competitive market.