How to manufacture toilet paper?

Toilet paper, a seemingly simple product, is an essential commodity that is used by millions of people around the globe every day. Its importance is often overlooked until it runs out, and only then do we realize its significance in our daily lives. Despite its simple appearance, the manufacturing process of toilet paper is anything but. It is a complex process that requires various steps to ensure the final product meets the demands and expectations of consumers. In this step-by-step guide of how to manufacture toilet paper, we will explore the manufacturing process of toilet paper, providing insights into the industry and the intricacies involved in creating this everyday essential.

Outline of how to manufacture toilet paper

- Raw Materials

- Pulping

- Paper Machine

- Drying

- Cutting and Packaging

- Quality Control

- Environmental Considerations

- Conclusion

Raw Materials

The journey of a roll of toilet paper begins with sourcing the raw materials. The primary raw material used in the production of toilet paper is wood pulp. Wood pulp is obtained from trees, specifically softwood trees like pine and fir, which have long fibers that provide strength and prevent tearing. The trees are cut down, debarked, and then chipped into small pieces. These wood chips are then processed to remove impurities and create a smooth, fibrous material that forms the base of the toilet paper.

In addition to wood pulp, other materials are also used in the manufacturing process. These include water, which is used in large quantities to create a pulp mixture, and chemicals, which are used to break down the wood chips and to bleach the pulp. Additives such as wet strength resins may also be used to improve the strength of the paper when wet.

Pulping

Once the raw materials are sourced and prepared, they are sent to a pulping machine. This machine is essentially a large blender that breaks down the wood chips into small fibers. The pulping machine mixes the wood chips with water and chemicals, creating a slurry. This process, known as pulping, helps to separate the fibers and create a pulp mixture that is suitable for making toilet paper.

The pulp is then cleaned to remove any remaining impurities, such as dirt or bark. This is done using a series of screens and centrifugal cleaners. The cleaned pulp is then ready to be turned into paper.

Paper Machine

After the pulping process, the pulp mixture is transferred to a paper machine. This machine is a large, complex piece of equipment that is responsible for transforming the pulp mixture into a continuous sheet of paper. The pulp mixture is spread evenly onto a wire mesh conveyor belt, known as the forming fabric. As the pulp travels along this belt, water drains through the mesh, leaving behind a mat of intertwined fibers.

This mat then passes through a series of rollers in a section of the machine known as the press section. Here, more water is squeezed out of the mat, and the fibers begin to bond together, forming a sheet of paper. The paper then passes through a drying section, where it is exposed to heated rollers or cylinders that remove any remaining moisture.

Drying

Once the paper has been formed, it is passed through a series of heated rollers to remove any remaining moisture. This drying process is crucial as it ensures that the paper is strong and durable, making it suitable for use as toilet paper. The temperature and speed of the drying process are carefully controlled to achieve the desired results.

The dried paper is then wound onto large reels, ready for the next stage of the process. At this point, the paper is still quite rough, so it is passed through a machine that lightly coats it with a lotion or wax to make it softer to the touch.

Cutting and Packaging

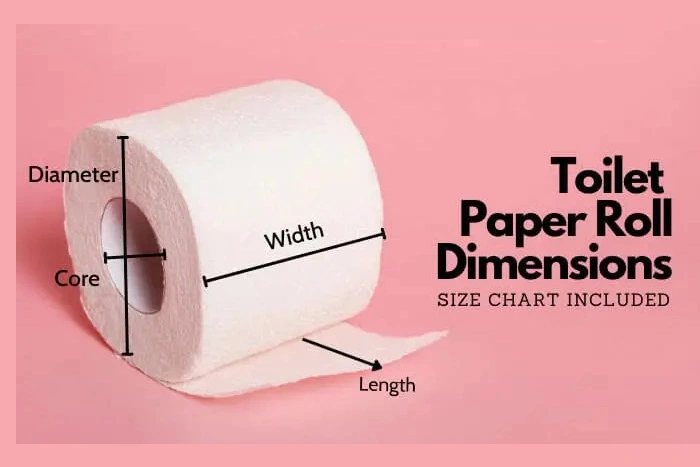

After the paper has been dried and softened, it is cut into individual sheets using a cutting machine. The size of the sheets can vary depending on the requirements of the market, but typically, they are around 4.5 inches by 4.5 inches. Once the sheets have been cut, they are wound onto cardboard tubes to create rolls.

The rolls are then packaged into individual wrappers or bundled into packs. The packaging process is automated and ensures that the toilet paper is hygienically sealed and ready for distribution. The packaged rolls are then boxed and prepared for shipping to retailers.

Quality Control

Throughout the manufacturing process, strict quality control measures are implemented to ensure that the toilet paper meets the highest standards. Samples of the paper are regularly taken and tested for a variety of properties, including strength, softness, and absorbency.

These tests are conducted in a laboratory and involve a range of equipment, from simple hand-held devices to sophisticated machines. Any defects or inconsistencies are identified and corrected to ensure that the final product is of the highest quality. This rigorous quality control process is crucial in maintaining the reputation of the manufacturer and ensuring customer satisfaction.

Environmental Considerations

The toilet paper industry is acutely aware of the environmental impact of its manufacturing process and has taken significant steps to minimize its carbon footprint. Many manufacturers now use recycled paper as a raw material, reducing the need for virgin wood pulp. This not only saves trees but also uses less water and energy than the process of making paper from fresh wood pulp.

Additionally, water and energy-saving technologies are employed to reduce waste and conserve resources. The industry is also exploring alternative materials, such as bamboo and hemp, which grow quickly and require less water and pesticides than traditional trees. These initiatives reflect the industry’s commitment to sustainability and its efforts to balance the demands of production with the need to protect the environment.

Conclusion

The manufacturing process of toilet paper involves several intricate steps that ensure the final product is of high quality and meets the demands of consumers. From sourcing the raw materials to cutting and packaging the finished product, each step is carefully executed to create toilet paper that is strong, soft, and absorbent. The toilet paper industry is also committed to minimizing its environmental impact through the use of recycled materials and sustainable manufacturing practices. By understanding the manufacturing process of toilet paper, consumers can make informed choices and support companies that prioritize quality and sustainability. This guide provides a comprehensive overview of the process, shedding light on the complexities involved in creating this everyday essential.