Introduction

Toilet paper is an essential product in our daily lives, but have you ever wondered, what is toilet paper made of? For B2B buyers in the tissue manufacturing industry, understanding the production process and materials used is crucial for making informed purchasing decisions. In this blog, we’ll take an in-depth look at how toilet paper is made, the materials involved, and the various aspects of toilet paper manufacturing that make it a high-quality, reliable product.

1. What Is Toilet Paper Made Of?

Toilet paper is primarily made from two types of paper pulp: virgin pulp and recycled pulp.

- Virgin Pulp: This pulp is made from wood fibers obtained from softwood and hardwood trees, such as pine, spruce, eucalyptus, and oak. Virgin pulp is known for its softness, strength, and absorbency, making it ideal for premium-quality toilet paper.

- Recycled Pulp: Recycled pulp is made from repurposed paper products like office paper, newspapers, and cardboard. It’s processed to remove inks, dyes, and contaminants, resulting in an eco-friendly and sustainable option for toilet paper manufacturing.

Some toilet paper brands use a blend of both virgin and recycled pulp to balance cost, quality, and environmental impact.

2. How was toilet paper made: The Manufacturing Process

The process of making toilet paper is intricate and involves several stages. Here’s a step-by-step overview of how toilet paper is made:

Step 1: Pulping

The first stage involves converting wood chips or recycled paper into pulp. This pulp is mixed with water and chemicals, then heated to break down the fibers. The result is a slurry mixture that forms the foundation of toilet paper production.

Step 2: Bleaching and Refining

The pulp is then bleached to achieve the desired whiteness and purity. This process removes impurities and ensures that the final product is soft and absorbent. Once bleached, the pulp is refined to adjust its texture and strength.

Step 3: Sheet Formation

The refined pulp is spread out on a large, flat screen to form thin sheets. These sheets are then pressed and dried to remove excess moisture, resulting in a continuous sheet of paper.

Step 4: Embossing and Perforating

To add texture and improve the paper’s softness and absorbency, the sheets undergo an embossing process. This creates patterns on the paper’s surface. The sheets are then perforated at regular intervals to make tearing easier.

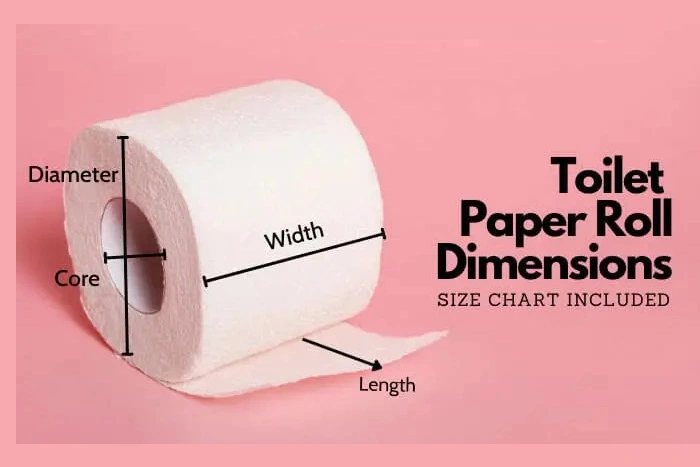

Step 5: Winding into Rolls

The final stage involves winding the sheets into large paper rolls. These rolls are then cut into smaller sections, resulting in individual toilet paper rolls ready for packaging and distribution.

3. How Is Toilet Tissue Made Different from Regular Paper?

Toilet tissue is designed to be softer, more absorbent, and more biodegradable than regular paper. This is achieved by refining the pulp to a higher degree, using softer fibers, and employing a unique embossing technique that enhances the paper’s texture and performance.

4. Where Is Toilet Tissue Made and Produced?

Toilet tissue is manufactured all over the world, with major production facilities located in countries like China, the United States, Germany, Japan, and Brazil. These facilities are equipped with state-of-the-art machinery for efficient and high-quality production. When asking, “where is toilet paper produced,” it’s essential to consider factors such as proximity to raw materials, access to technology, and market demand.

5. How to Make Toilet Tissue Paper: Key Factors in Production

Producing toilet tissue paper requires specialized equipment, skilled labor, and quality raw materials. Here are some key factors involved in toilet paper manufacturing:

- Quality of Pulp: The choice between virgin and recycled pulp greatly influences the final product’s softness, strength, and absorbency.

- Machinery: Advanced machinery is used to refine the pulp, press the sheets, and wind the rolls. Investing in high-quality equipment ensures efficient production and consistent quality.

- Environmental Considerations: Many manufacturers focus on sustainability by using recycled materials, reducing water consumption, and minimizing energy use.

6. Paper Roll Manufacturing: The Role of Technology

Technology plays a significant role in the paper roll manufacturing process. Modern factories use automated systems to handle everything from pulp preparation to roll cutting and packaging. These technologies not only improve efficiency but also ensure that the toilet paper meets high standards of quality and hygiene.

7. The Toilet Paper Industry: Trends and Insights

The toilet paper industry is a dynamic and evolving market, influenced by factors such as sustainability, cost efficiency, and consumer preferences. Here are some trends shaping the industry:

- Eco-Friendly Products: With growing environmental concerns, there’s a rising demand for toilet paper made from recycled materials and sustainable resources.

- Customization: B2B buyers often seek customized options, such as different roll sizes, packaging, and branding, to meet specific market needs.

- Innovations in Softness and Strength: Manufacturers are constantly developing new techniques to enhance the softness and durability of toilet paper, catering to a wide range of consumer preferences.

8. Frequently Asked Questions (FAQs)

Q1: How do you make toilet paper softer?

Manufacturers use a combination of virgin pulp, refining processes, and embossing techniques to create a softer texture.

Q2: Where is the majority of toilet paper made?

The largest producers of toilet paper include China, the United States, Germany, and Japan, where major facilities are equipped with advanced technology for mass production.

Q3: How to make paper toilet rolls more sustainable?

To create more sustainable toilet paper rolls, manufacturers can use recycled materials, eco-friendly packaging, and energy-efficient production methods.

Q4: How is toilet paper produced in bulk?

Bulk production involves large-scale machinery that processes, refines, and converts pulp into massive rolls, which are then cut into individual toilet paper rolls for distribution.

Conclusion

Understanding what toilet paper is made of and the process behind how to make toilet paper is essential for B2B buyers looking to source high-quality products. From the raw materials used to the advanced manufacturing techniques, every step plays a role in producing a product that meets the demands of today’s consumers.

Ready to source premium toilet paper for your business? Contact us today to learn more about our high-quality, customizable tissue products and how we can meet your B2B needs.